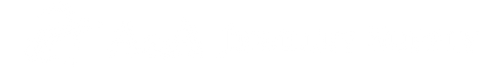

Elettrolaser MS 165 — Laser Welding System

Contact us for Financing Options!

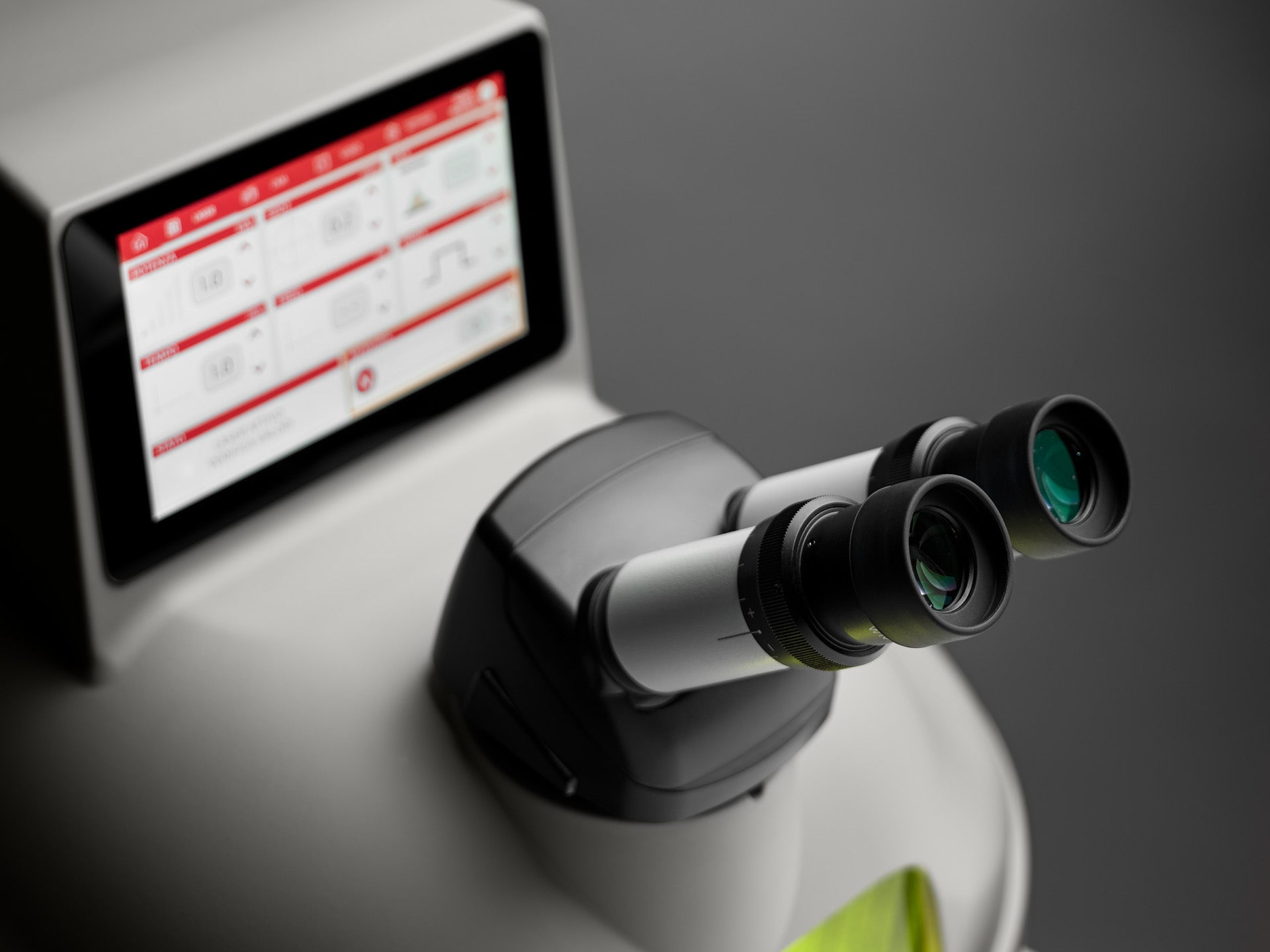

The Elettrolaser MS 3.5-165 is a high-performance laser welder engineered for precision and productivity in jewelry, dental, and industrial applications. Combining cutting-edge Italian technology with user-friendly operation, the MS 3.5-165 offers exceptional welding quality on a wide range of precious and non-precious metals including gold, platinum, chrome cobalt, steel, palladium, silver with and without the addition of wire. Its water and efficient forced-air cooling systems ensure consistent performance during prolonged use, making it the ideal choice for workshops seeking reliability, speed, and superior welding results.

Designed with a spacious working chamber, touch-screen interface, and customizable welding parameters, the MS 3.5-165 enables operators to perform delicate repairs, intricate joins, and high-volume production with minimal heat impact on surrounding areas. Whether you’re repairing prongs, sizing rings, creating custom designs, or performing detailed micro-welding, the Elettrolaser MS 3.5-165 delivers outstanding precision and control.

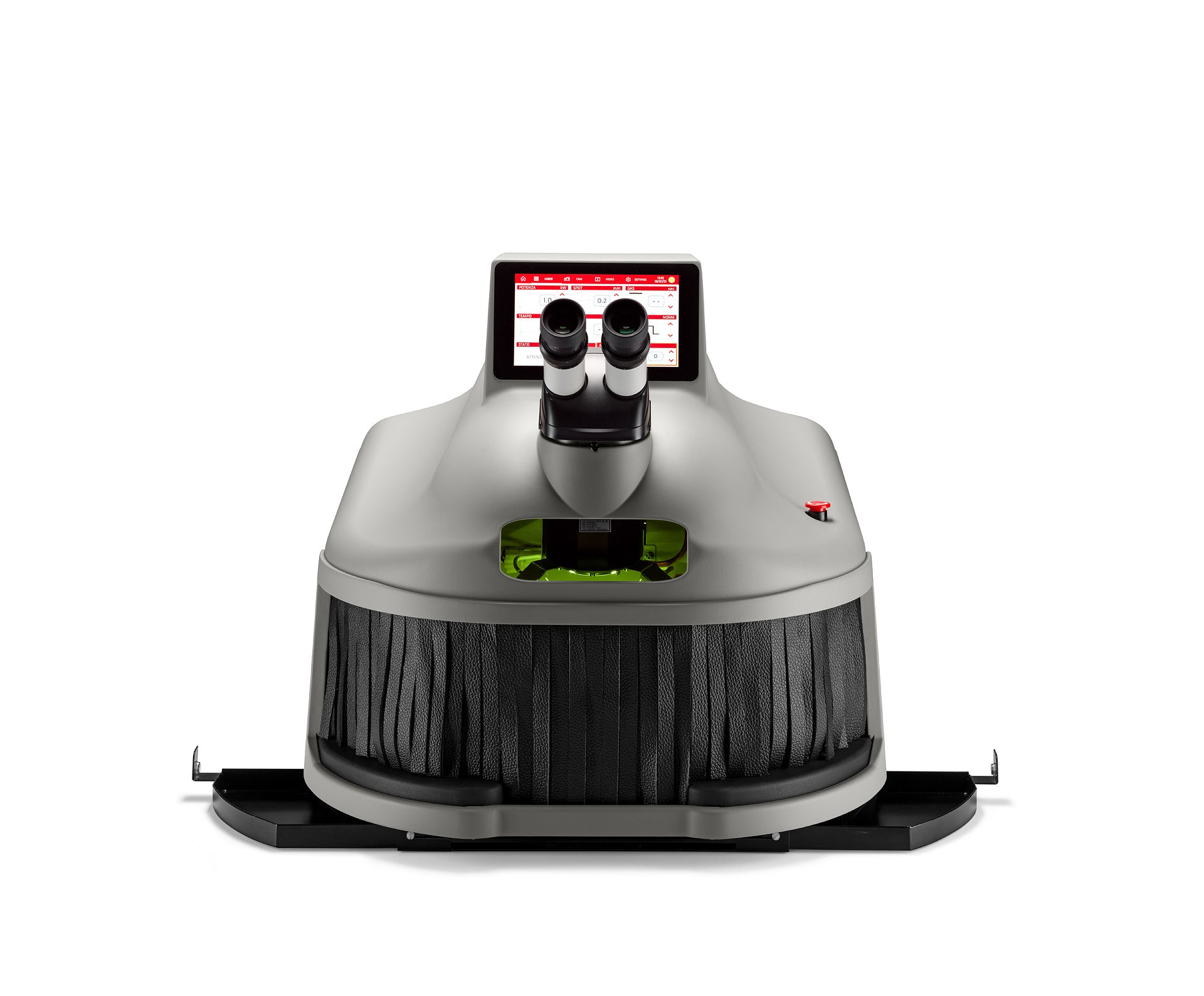

Designed for Comfort and Efficiency

-

Advanced features include:

-

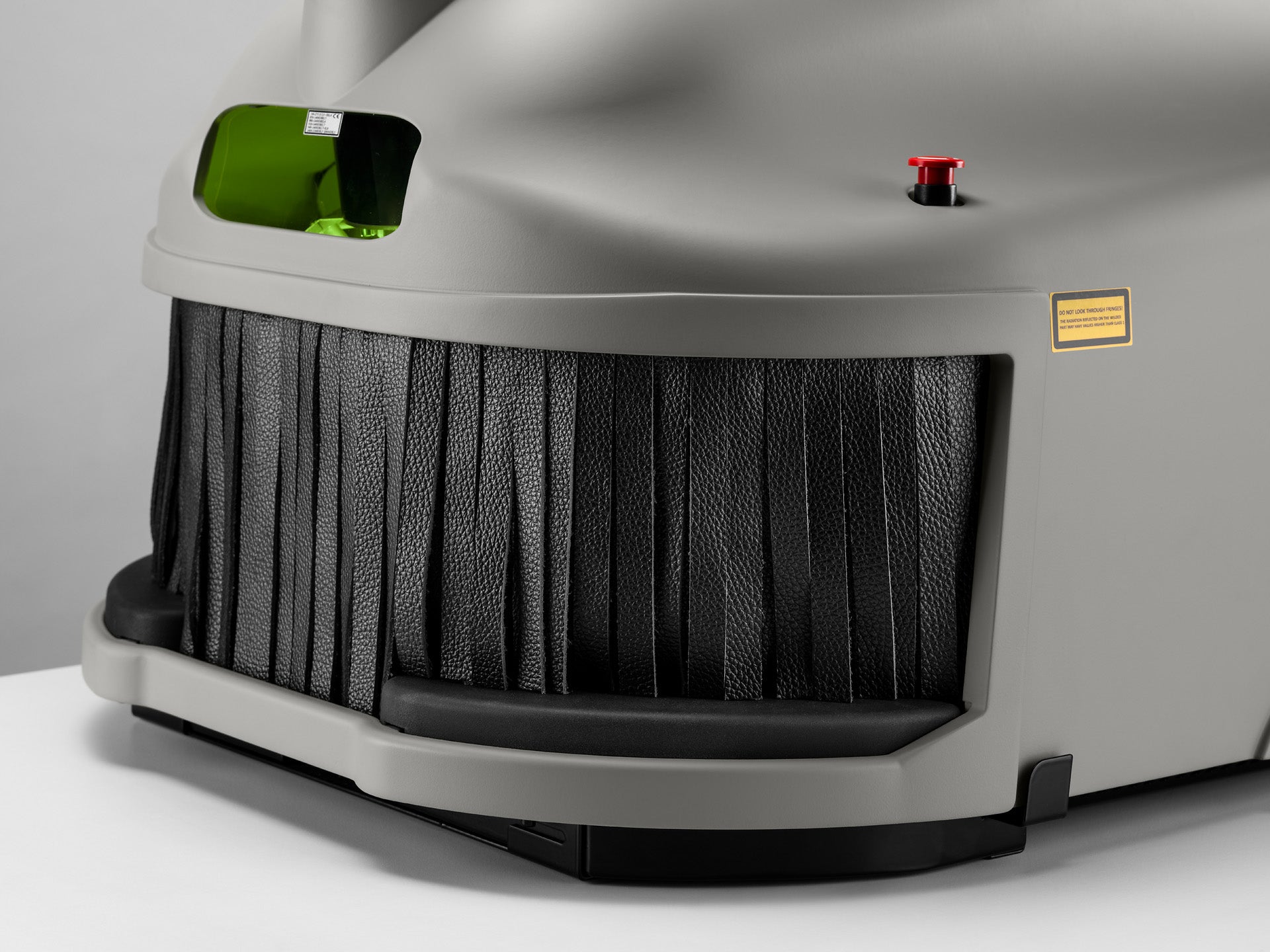

Argon gas inlet for welding in inert atmospheres

-

WiFi connectivity for remote access and updates

-

Built-in tutorial videos for quick operator training

-

100 programmable memory presets

-

Large 7” color touchscreen interface

-

High-quality Leica stereo microscope for exceptional visual clarity

-

-

Backed by a comprehensive 3-year warranty for peace of mind.

Technical Specifications – MS 165

-

Laser Source & Wavelength: Nd:Ce:YAG, 1064 nm

-

Average Power: 75 W

-

Peak Power: 6.5 kW

-

Max Energy: 165 J

-

Pulse Duration: 0.1 – 25 ms

-

Pulse Frequency: 0.5 – 20 Hz

-

Spot Diameter Range: 0.2 – 2.0 mm

-

Spot Adjustment: Motorized

-

Pulse Shaping Programs: 6 presets

-

Memory Capacity: 100 program slots

-

Internal Chamber Control: Joystick

-

External Control Interface: 7” Color Touch Screen

-

Power Supply: 1100 V AC, 50/60 Hz

-

Argon Nozzle: Yes

Typical Applications

-

Welding precious metals such as platinum, titanium, gold, silver, and palladium

-

Restoration of antique jewelry

-

Repair of stone settings without needing to remove gemstones

-

Repair of tennis bracelet clasps

-

Maintenance and repair of watches, eyewear (including nose pads, hinges, and frames), and other fine components

-

Welding using filler materials with minimal post-processing

-

Correction of casting defects like porosity or cracks

-

Dental work, including repair of bridges, implants, prostheses, and orthodontic devices

-

Mold and die repair

-

Welding in areas difficult to access with a traditional flame or arc welding tools

Customer Reviews

No reviews yet Write a review